-

How many stripping ways of die-cutter ?

The first one is the most common and lower cost. The waste removal by upper and lower thimbles and intermediate stripping plates is characterized by lower cost and reusable waste removal tools. However, it takes a long time to adjust it and not easy for job change over. which is more suitable for medium and short term jobs. If job changed, it would preparaed a lot of thimbles and several sets of stripping frames need to be stored and adjusted in the site for future use.

The second one is that the die supplier makes a complete set of upper and middle stripping plates, which cooperate with the lower thimble. the customized stripping model would took higher cost but fast adjustment, quick job change over which is suitable for long order products.

The third is dynamic stripping, also known as master striping, which can be translated into "master stripping". But due to higher cost it is not popular as above ones.It is a excellent solution for the narrow and small special-shaped stripping, and could reduce the possibility of the plugging as well as quick job change over.

-

The importance of Floor Plan for Die-cutter machine

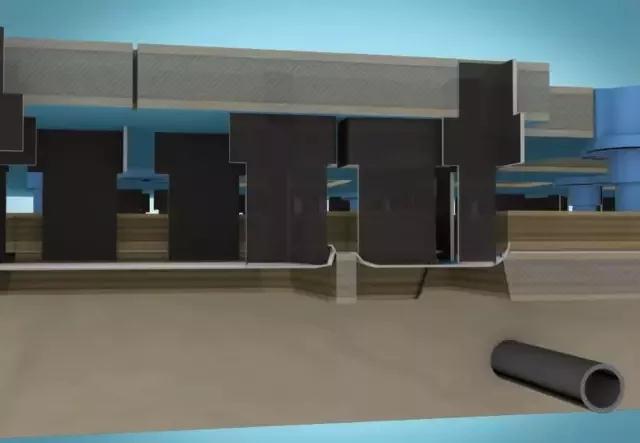

The floor plan of printing machine is very important for many printing factories, while floor plans of diecutting machine have not earned enough attentions. It’s not proper to set foundations of diecutters simply according to machine weight. Compared with printing machine , floor plans for diecutters are more demanding in the same installation condition.

As for printing machine, the sheets are transferred between wheels. The whole process requires a high level of horizontality. If the foundation is compact, the horizontality will not change after completion, and the printing quality and equipment reliability are guaranteed. As for flatbed diecutting machine, though the paper is also conveyed on a horizontal surface, it will have a huge load during operation, and act a reciprocating force on the ground. It is difficult to ensure the foundation level and load in a long term. When the machine is running at a certain frequency, the impact on the foundation and the whole machine is extremely serious. It is conceivable that if the machine is placed on an overhead steel plate, the steel plate will bend up and down to a certain extent when the machine is running. When the bending frequency of the steel plate reaches the resonance point, the consequences would be disastrous.

Before discussing the importance of die-cutting floor plan let's take a look at what kind of ground does not meet the requirements.

The common cases where the foundation does not meet the installation requirements are as follows: The thickness of the concrete is not qualified, the concrete label is too low or too high, the area is too small, the steel is not placed, or the foundation of die-cutting section is treated differently from that of the feeder and delivery sections.

In view of the above situations, the foundation fastness and horizontality will inevitably change. Then what kind of problems will happen to the equipment ?

First of all, it will cause the unbalance of die-cutting pressure. The die-cutting pressure fluctuates greatly. The pressure of a certain angle changes nonlinearly, and the pressure-compensation effect cannot be achieved. The reason is that the support frame of the main platform is in a state like “hanging” due to the horizontal change. In addition to affecting the quality of the product, it will greatly increase the loss of the cutting die. At the same time, the load on the internal support frame of platform will be unbalanced over the years, which will cause damage to related components. For such a situation, it is more difficult and time-consuming to find problems or to follow up the part-replacement.

If no steel bars are placed in the foundation, or the number and specifications of the steel bars do not match due to different standards, the foundation of the diecutting station may sink or cracked, causing the feeder and the delivery sections are not on the same horizontal surface as the diecutting station. The high-speed running and the introduction to front lay could be unstable, which may affect the positioning accuracy at front lay during high-speed feeding.

Secondly, since the delivery section is not at the same horizontal surface as the diecutting platform, there will be displacement of the originally fixed position of wall plates and the diecutting platform. The horizontal position of the chain guide will change accordingly, and the chain guide loss will be caused. Hence the chain will be easy to be elongated. The noise of the equipment becomes loud, and the load on both sides of the chain will be uneven, resulting in unstable positioning and diecutting accuracy.

On the whole, due to the problems of the floor plan, the productivity of the equipment will not achieve the expectation, but with loud noise and poor precision. The equipment installed only for 2 years may run like an old machine.

Therefore, it is a priority to strictly follow the floor plan of the die-cutter manufacturer. For different installation environments, such as hilly areas, coastal or sea-reclamation areas, or equipment are not installed on the ground floor, in addition to the manufacturer's floor plan, please consult the local design institute to get a safe and reliable foundation solution!

-

Questions on die-cutter

1) Q : is die cutting, indentation processing ?

A : Die cutting is a processing procedure that steel blades are used to form dies (or steel plates are used to carve die frames) and the printed products are rolled and cut into a single graphic product on the die cutting machine.

2) Q : What is the process flow of die cutting and indentation ?

A : Bottom plate slotting - steel knife (line) side cutting, molding - row (inlay) knife (line) - stick (plug) rubber

3) Q : What are the characteristics of the steel plate used as the base plate material of the die-cutting indentation plate ?

A : Too thick steel plate is difficult to cut, and frame material is too expensive, so steel frame is also used to make composite die-cutting plate, which means that the upper and lower layers would be 3mm thick steel plates, and the middle layer is 12mm thick wooden plate. The die-cutting plate is solid and durable even the cost is expensive, and the knife could be changed many times (up to 40 times). For the pattern job, because the tool can be changed for a long time (which is half price of die-cutting plate), the cost can be reduced, and the quality of die-cutting is good, which is worthing. ETERNA's die cutter are made of steel plates

-

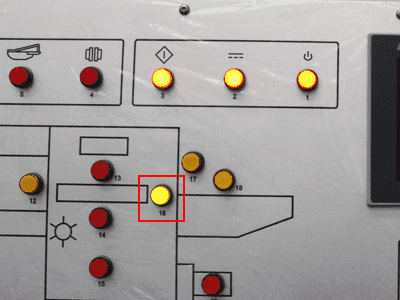

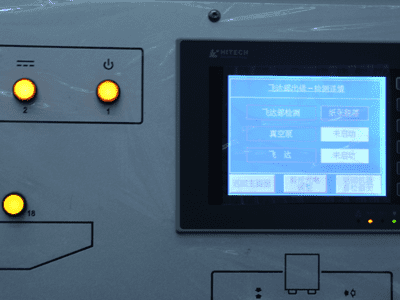

ECUT 1620 NO. 16 LIGHT ALARM

- Check if the sheet arrive the gauge

-

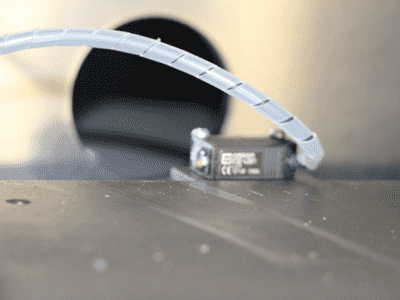

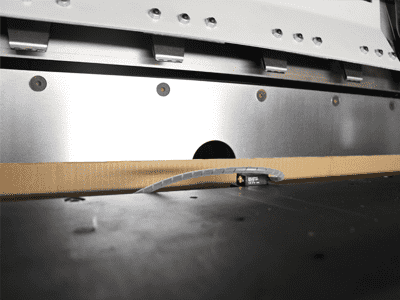

Check the photoelectricity

if no sheet on photoelectricity

if have sheet on photoelectricity

-

Check the reason for sheet could not arrive the position

lower front baffle

air suction too small

warped sheet paper

gripper collide with the sheet

wrong feeding time

1 2.a

2.a 2.b

2.b

-

Reason for ECUT 1620 Light Alarm

Sheet paper exceed

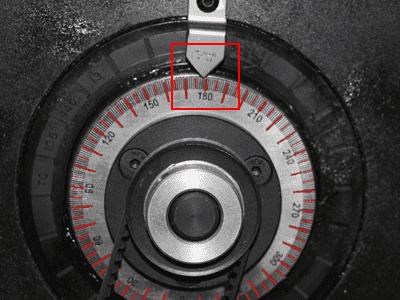

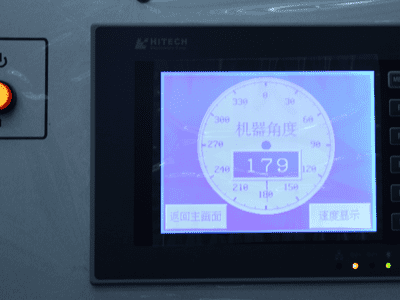

- Check if the mechanical angle and electrical angle are synchronous

- Check photoelectricity

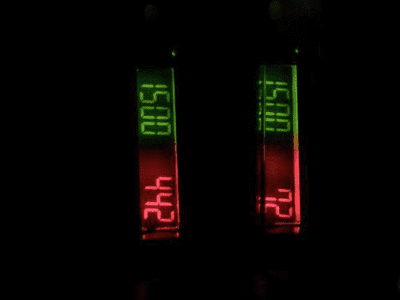

If there is no sheet under the photoelectricity, the green light will on

if there is sheet under the photoelectricity, the green light and the red light will be on together

- Check if the paper feeding time is too fast. Under normal circumstances, the paper edge reaches about 237 degrees under photoelectricity

1 1

1 2.a

2.a 2.b

2.b 3

3

Paper Dropped Off

- Paper arrived the front gauge, but gripper doesn't hold the paper, so the alarm happens during operation

- When gripper grabs the paper, the photoelectric detection for length of the paper and for front gauge will give an alarm , aslo would adjust the photoelectric sensitivity of the front gauge (when reaches the lowest point, the photoelectric detection of the front gauge cannot light on the paper)

1-2